Specification cleanroom wall type TWS-80-EPS

Products

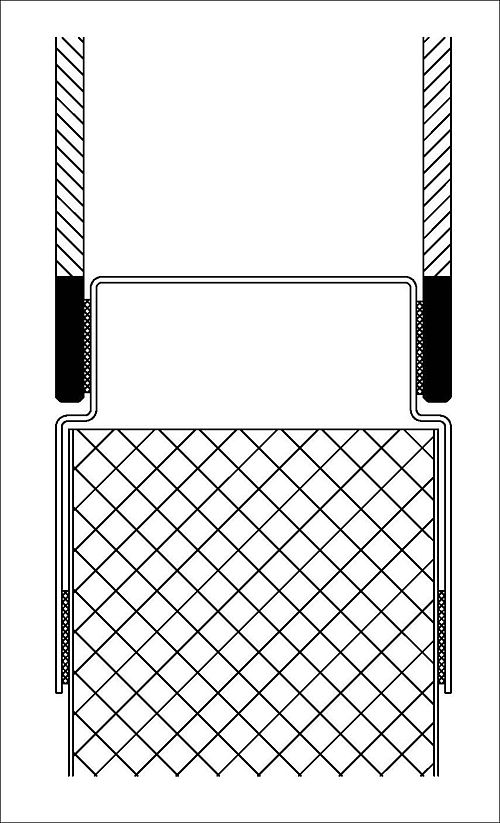

Description of wall construction

The monoblock element consists of two steel plate shells, which are connected to each other by an EPS core. The elements are placed face to face with each other.

Planking and surface

High quality corrosion-resistant sheet metal. All visible surfaces powder-coated in a baking process based on polyester and epoxy resins. Layer thickness on average 80 μm, at least 64 μm. The surface is completely smooth with a low degree of gloss, other coating techniques (fine structure, etc.) are possible. The surface is abrasion-resistant, easy to maintain and resistant to repeated cleaning with commercially available disinfecting and cleaning agents and withstands gassing with hydrogen peroxide.

Components made of pre-coated material are not used! All visible parts are coated after the mechanical processing, such as punching and edging!

All materials, except seals, non-combustible

Color: RAL to choice

Standard dimensions

Shell thickness

- Sheet thickness: 0,9 mm

Wall thickness

- 80 mm

- special wall thickness possible

Wall width

- Standard grid 1200 mm

- grid dimension of 200 - 1450 mm possible

Wall height

- up to 3800 mm without horizontal joint

- over 3800 mm with attached elements (horizontal joint)

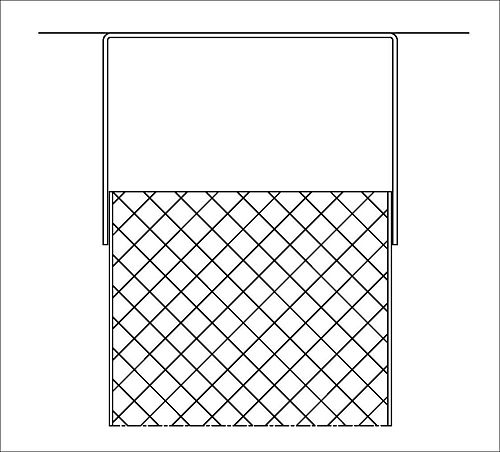

Glazing

full wall

Double glazing with 2 x ESG 6 mm (toughened safety glass)

Cut-outs for glazing are made on site. The cutting edges are covered with the glass frames.

The glass is glued on both sides flush with the inserted glass frames on both sides and jointed by silicone, the replacement of the glazing is possible without removal of the wall element.

Glass interior permanently dust and fog free, with surrounding passepartout in RAL color as desired.

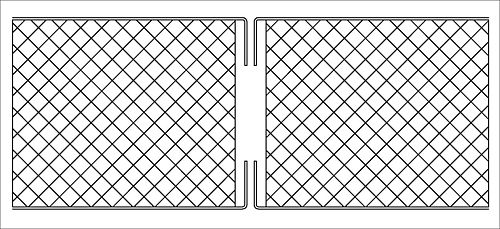

Whole glass wall

Single glazing 1 x ESG 12 mm (toughened safety glass)

Mounting as an entire wall element.

The glas is positioned in the middle oft he wall element and is jointed by silicone, the replacement of the glazing is possible without removal of the wall element.

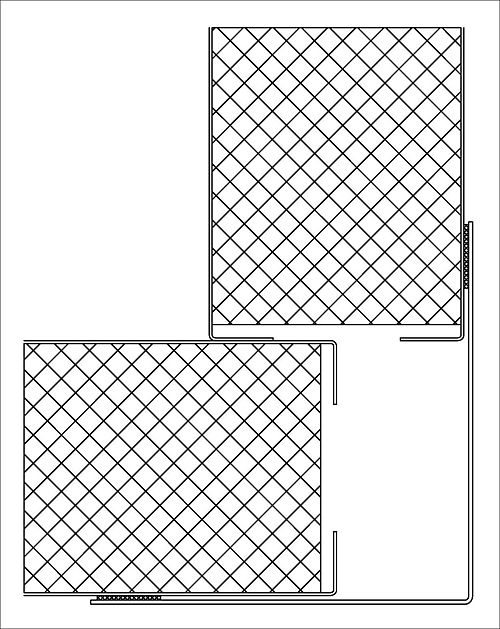

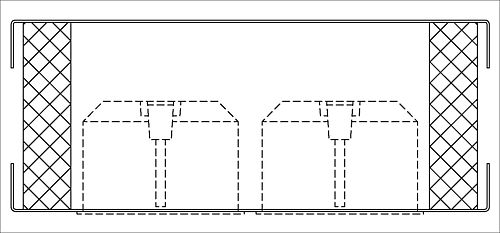

Laying of cables and pipes

By using installation elements - standard width 200 mm - installation of electrical cables and pipes up to 70 mm diameter on a width of 150 mm possible.

It is also possible to install switches, plug-sockets and function switches in the installation elements.

Advantages

- All wall elements are planned and manufactured according to the project. There are no standard wall elements. Element widths and heights can be varied.

- For installation elements, a cavity for installations of approx. 70 mm remains in the wall.

- Individual removal of each wall element is possible.

- Powder coating is performed after mechanical processing (punching, edging), i.e. Reduced risk of surface damage - at least 64 μm, on average 80 μm.