Cleanroom Construction

Info

ECOS GmbH - Cleanroom construction made in Austria

Our company specialized in the manufacturing and extension of cleanrooms. We are located at Kirchberg am Wagram (~70 km west of Vienna) and provide cleanroom construction services for customers in Austria, Germany and all over Europe.

General information

We cover all aspects of cleanroom construction from the planning phase to production and assembly of cleanrooms. During the planning stage and conception we tightly collaborate with our customers, architects and technical planners.

We produce all necessary cleanroom components ourselves (for example cleanroom walls, cleanroom doors or cleanroom ceiling panels) and the assembly of the cleanrooms is done by our experienced assemblers.

Product portfolio

Cleanroomwall Type-VST

Fitted to customer requirements; Used in cleanroomclass A and upwards; with or without fire protection capabilities according to standards E100 or E190.

Cleanroom Ceilings

Either walkable or non-walkable and in different grid dimensions available. Available with: water repellent or hygroscopic surface, pressure resistant up to +/- 300 Pa.

Cleanroom doors

Nearly no restrictions regarding locking systems or automatization; with or without fire protection capabilities according to standards E100 or E190.

Cleanroom glazing

Solid wall (double glazing), full glass wall (single glazing)

Read more

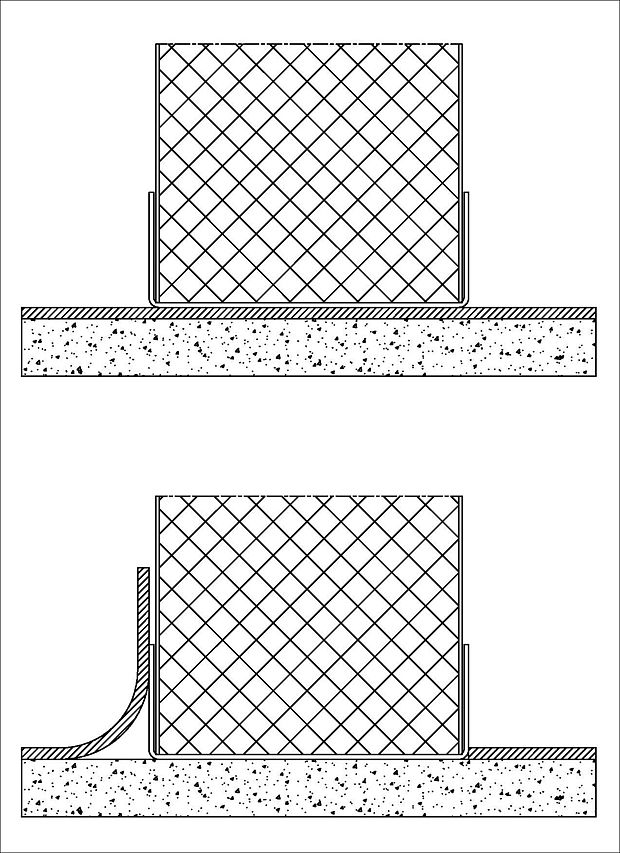

Partitions

Prefabricated steel monoblock partition system, impermeable sealing, the monoblock system achieves minimal space requirement. high combinability and usability

Read more

Custom solutions

Our base system is easily extendable by using add-ons such as personal airlocks, material airlocks, media ducts etc.

Highly flexible and easily integrated

All cleanroom-wall and -ceiling-systems built by us are flexibly applicable and nearly all processing-, sanitary- or electronic components can be integrated.

Cleanroom surfaces can be done in stainless steel V2A (1.4301) / V4A (1.4571) or with a RAL colour powder coating.

Cleanroom classifications

Our cleanrooms, cleanroom ceilings, cleanroom door systems, cleanroom glazings, are used at positive and negative air pressure in different cleanroom classifications according to ISO 14644-1 (ISO 5 – ISO 9) or GMP Annex 1 (cleanroom class A to cleanroom class D) respectively.

Cleanroom Filtration Systems / Air Filtration Boxes / Cleanroom Lighting Equipment / Cleanroom equipment

All cleanroom components like cleanroom filtration systems, air filtration boxes or cleanroom lighting equipment can be integrated as flush surfaces into our cleanroom wall and cleanroom ceiling systems.

When planning our cleanroom systems we take into account various cleanroom equipment and processing facilities.

Likewise the components that are used in our cleanroom door systems are connected to monitoring systems.

Blower Door Test

At our company‘s location we have a testing facility at our disposal where we evaluated various different cleanroom door systems at varied differences in pressure (10 – 100 Pascal) for impermeability. We are happy to offer those results at the planning phase for new cleanroom systems.

Resistance to cleaning agents and disinfectants (H2O2 Hydrogen peroxide)

Since cleanroom disinfection is usually done using regular cleaning agents and disinfectants our systems were built to be resistant to them. All edges are powdercoated after stamping the components to prevent bare or blank spots.

If your company plans to use certain types of cleaning agents or disinfectants we are happy to perform resistance tests on our powdercoating.

The technical university of Graz already conducted resistance tests of our cleanroom wall and cleanroom ceiling systems concerning hydrogen peroxide (H2O2).

A list of commercial cleaning agents and disinfectants that are useable in our cleanroom systems is readily available and will be produced as necessary.

Cleanroom silicone

To produce airtight seals at the seams we exclusively use certified cleanroom silicone.

Qualification and Validation

We will deliver the necessary documentation in advance as necessary.